-

Order Processed Within 24 Hours

-

30-Day Money-Back Guarantee

-

24/7 Customer Support

-

Friendly Customer Service

Easy to Print

ArtiShape PLA filamen stands out for its high print speed.

Consistently high quality printing without extensive adjustments to print settings

Unique technologies

Toughened and hard break filament with ArtiShape's unique technology.

Significantly different from other filaments

Biodegradable

Made from natural corn and grain, which well-knowed

for their environmental friendly properties allowing the

ArtiShape PLA Filament to degrades naturally in nature.

At the forefront of the industry

We have the latest technology in the industry and we are committed to being user-oriented. We are committed to creating extraordinary filament.

FAQs

Q: Why is my printed object not sticking to the heated bed? How can i dolve this?

A: The nozzle may be too far from the bed. Ensure that your heated bed is leveled and clean. Also, check if the printing temperature and bed temperature are too low and adjust them to the correct range. When using specialty filaments such as glow-in-the-dark, ABS, ASA, etc., it's recommended to slow down the first layer print speed for higher success rates.

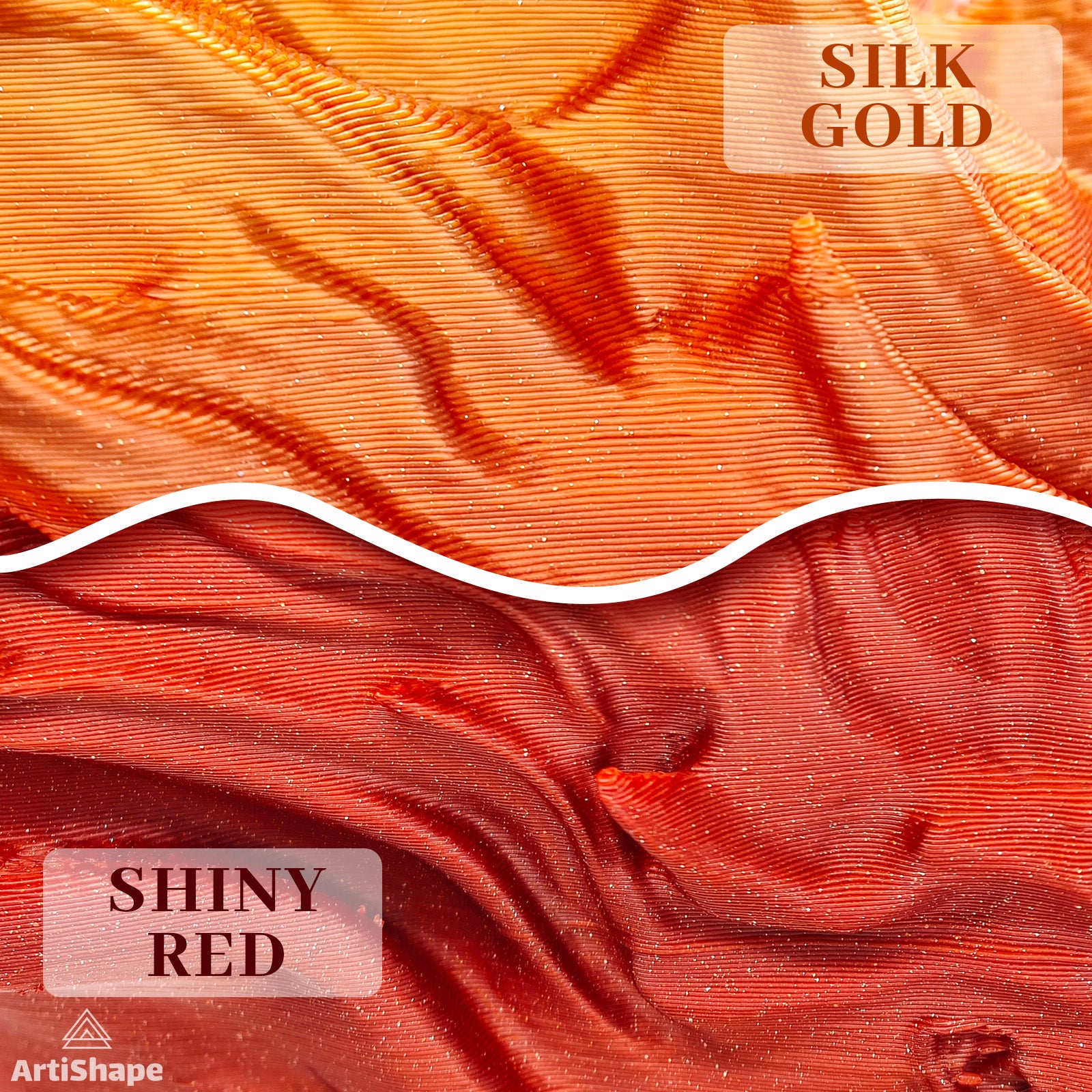

Q: Why does my silk filament print lack glossiness?

A: The print speed and temperature may not be properly matched. When printing at high speeds, users need to increase the print temperature to achieve the desired glossiness of silk filament. Another method is to decrease the print speed for outer walls to obtain better glossiness, with a recommended speed of 50-70mm/s.

Q: Why is my filament tangling? How can i solve this?

A: Filament tangling is not caused by improper winding or imperfections. According to the manufacturing process of filament, it is wound back and forth (from left to right, then from right to left). Under normal circumstances, there should be no tangles. Common causes of tangling are the filament end not secured in the appropriate hole of the spool. Excessive tangling or changing the winding direction leads to filament tangling. Therefore, customers need to secure the filament end in the proper hole of the spool.

Q: Why is my PLA print not sticking to the heated bed? How can i solve this?

A: The nozzle may be too far from the bed. Ensure that your heated bed is leveled and clean. Also, check if the printing temperature and bed temperature are too low and adjust them to the correct range.

Q: Why do I have severe stringing in my printed models? How can i solve this?

A: Lowering the printing temperature can effectively reduce stringing. Adjusting your retraction length and retraction speed in the slicer settings is also an effective method. However, make sure your filament is not affected by moisture.